ENGIRO – competent solutions

ENGIRO is a family company driven by first-class development expertise, with a dedicated team and a technical and entrepreneurial background of over 30 years, embedded in the high-tech region of Aachen.

We are one of the technology leaders for highly efficient, innovative electric motors and power train solutions. Our proprietary e-drives and our comprehensive expertise in power trains make us the partner and supplier of choice for system integrators and OEMs in our markets including construction, municipal, marine, trucks, agriculture and industrial vehicles. ENGIRO is also our sustainable and economic response to the demanding environmental challenges of a rapidly changing world.

Our expertise

- Design and state-of-the-art simulation, adaptation and optimisation of e-drives and integrated power trains including battery systems: mechanical, electrical, magnetic, thermal, stationary + dynamic

- Integration of relevant system concepts: fully electric, hybrid, regenerative

- Application-specific expertise: commercial shipping, utility vehicles and special areas of the automotive industry, industrial and stationary solutions

- Network and partnerships with select technology experts in engineering, research and development, universities

Milestones

2022

ENGIRO enters into a strategic partnership with the HYDAC Group.

2020

10 years after its foundation and the first year at the new production site, Jan Werner joins the management board

2019

- Move to the new ENGIRO headquarters with production site and office building in Aachen

- Product launch: New 260 W e-drive series (32-342 kW)

- Airborne: successful maiden flight with ENGIRO power train

2018

- Product launch: New 205 W e-drive series (5-117 kW)

- ISO 9001 certification

2017

Development of the new e-motor generation for series production

2016

Product launch: 40 kW range extender for utility vehicles

2015

Test bench for extensive e-drive + system tests and optimisation

2013

- Product launch: 2x10 kW range extender for marine applications

- New production facility with enhanced capacity

2012

200 kW hybrid e-drive for utility vehicles and marine applications

2010

ENGIRO GmbH, founded by Dr.-Ing. E.A. Werner and supported by renowned industry and research partners

1990

Dr.-Ing. E.A. Werner founded his engineering company ISATEC GmbH with today more than 30 years of experience today in structural analysis, design, simulation and optimisation of technical and electrical components and systems in various industrial and commercial sectors

Simulation & calculation

ENGIRO is characterised by its own development and manufacturing of electric motors.

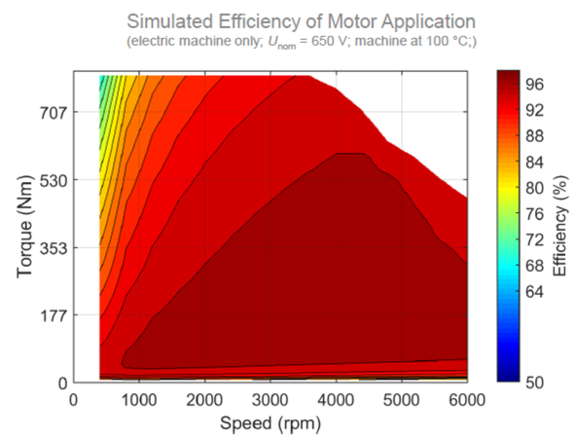

It starts with initial design studies, geometric pre-dimensioning, modular concepts and shifting designs for different operating parameters. Subsequently, the solution versions are supported further by simulating and optimising electromagnetic properties, mechanical and thermal optimisation as well as coordination with different power electronics. Finally, all production-ready documents, test specifications and documents are created.

An essential tool for designing and optimising our highly efficient electric drives is the numerical magnetic field calculation. In the theoretical stage, the finite-element method (FEM) is used to design the way the magnetic fields are formed and to calculate how magnets and coils must be arranged under certain boundary conditions in order to optimise the magnetic field lines for specific applications. For these FE-calculations we use the programs like ANSYS, Infolytica and others.

The simulation calculation also covers operating strategies. Here, logical relationships are run through to simulate energy management in particular. We carry out these calculations using the program Matlab Simulink.

ANSYS is used for mechanical and dynamic calculations, e.g. to optimise rotors under centrifugal force, to safely transmit torques or to avoid resonance.

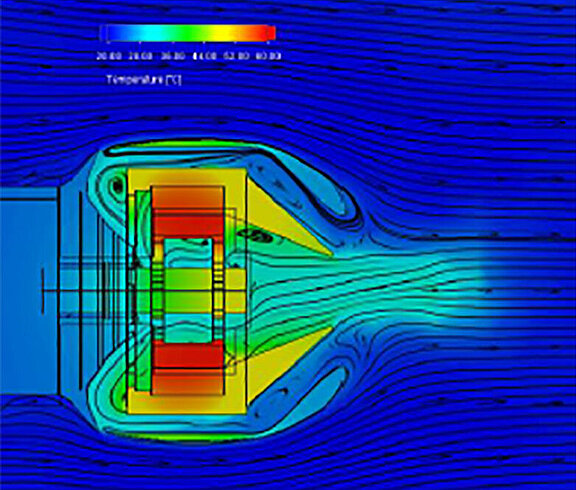

Fluid calculations with superimposed heat transfer are carried out using FloEFD at our sister company ISATEC.

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/e/4/csm_IVT2024-Engiro_Vorank%C3%BCndigung_ab2d7d409e.png)